The holiday rush is upon us, and many retailers are already preparing for the busiest shopping days of the year, also known as Peak Season for sales and shipping. Since this is a make-or-break time for many businesses, shipping disruptions can lead to lost sales and unhappy customers for your clients. No one wants that!

The solution is to maintain good relationships with your clients by getting their orders out on schedule. This will help ensure continued business throughout the rest of the year. Here are some tips on how to prepare your warehouse or 3PL for peak season so you can avoid complications and come out on top.

Definition of Peak Season

Peak season refers to the period when demand for products rises sharply due to seasonal events such as holidays and special occasions. This means that there will be more people buying items than usual, so retailers need to make sure they have enough stock available to meet the increased demand. This is where your warehouse or 3PL comes into play. You can help your clients meet their seasonal sales goals, ultimately reaching your storage, shipping, and profit targets.

Warehouse Operations Expectations

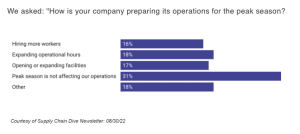

Since the beginning of the pandemic, supply chain issues have become a continual part of doing business. Addressing and preparing your warehouse for peak season “as usual” is no longer applicable. Too many variables in the market now exist that will make it harder to predict your peak season planning forecast. Some relevant issues to note include:

- Additional supply chain problems (backed-up ports, container backlogs, protests, strikes, rising fees, etc.)

- Changes in customer buying patterns

- Increased holiday inventory

- Labor shortages

- Unpredictable fuel prices

- Low carrier capacity leading to e-commerce shipping surcharges

- Inflation and/or a potential recession

- Possible Covid resurgence

Start Preparing a Plan and a Budget

Customer support is key to a successful season. Lost shipments, damaged items, shipping delays, and returns are bound to happen no matter how well your warehouse or 3PL distributes holiday orders during this busy time. Be sure to focus on customer satisfaction, quality control, and warehouse efficiency.

Carrier shipping times will fluctuate. According to an article by DC Velocity, global air freight demand dropped 9% in July as compared to July 2021. However, your warehouse manager should be prepared to ship items earlier than you would any other time of year. Learn each carrier’s strengths and weaknesses so you are not sidelined with an unanticipated problem. Continual carrier communication is key to success in getting your clients’ products into consumers’ hands in time. In addition, air freight rates also dropped in July, yet remain still historically high – up 11% over last year – so it is important to budget accordingly.

Stock up on packaging materials. Packaging supplies are essential for any business, especially during peak season. Consider the current supply chain climate when purchasing what you need to meet demand. In a recent Supply Chain Dive article, John Blake, senior director analyst with the Gartner Supply Chain practice, noted that packaging supply is expected to remain tight through the holiday season. “Currently we’re seeing six months’ [lead time] where it used to be four to six weeks,” he said. “Things like labels have 12 to 16-week lead times, where it used to be four to six.” With supplier expectations about production schedules changing, companies need to talk with their suppliers now and figure out where they will be in the next four to six months.

Don’t ignore your workforce. In today’s competitive environment, 3PLs and warehouses need to do everything they can in order to keep up with their competitors. One way is by offering attractive benefits and programs that will attract new warehouse workers, retain existing employees, and keep the operation running smoothly. That’s because without an active workforce you could soon find yourself facing major disruption.

Peak season also means that those working in your distribution centers will more than likely be working extended hours. Make sure that your company or 3PL is adequately staffed, even if you need to bring in temporary employees to maintain warehouse efficiency. Keep your workers’ morale up with pizza and donut deliveries for those late nights or early mornings.

All of these considerations should be planned strategically and budgeted to streamline processes before holiday shopping begins.

Strategies for Predicting Holiday Season Warehouse Volumes

There are several ways to predict peak season distribution center volumes. One method is to use historical data to determine how much inventory to have on hand which translates into warehouse space used. Another option is to forecast future demand based on past trends. A third option is to estimate current demand based on previous seasons’ sales.

Obviously, planning ahead is the best way to have a successful peak season. You can do this with the following forecasting strategies for your fulfillment services.

1. Inventory Data

Inventory management and forecasting are all about data. Before you can figure out what you need to order and when you need to order it, you need to understand your historical numbers. While it is not a perfect solution given changing conditions, this is a good starting point for peak season forecasting. Your warehouse management system (WMS) software should be able to provide you with historical data over several years, as well as assist in forecasting for the peak season and planning floor space for products.

2. Always Take Notes

The best teacher is past experience. It is not enough to just take notes on what happened during peak seasons or periods of high inventory. Your team will only be able to make accurate predictions for future markets if they know how things work after the fact. Plus, memories fade with time. Take notes throughout the year about all aspects related to the market activity – shipping percentages and punctuality, order levels, and labor hours – in order to refer back to them when planning for the next holiday rush.

3. View Real-Time Inventory

It can be tough to know what you need for your operation if the data isn’t accurate and timely enough. With real-time inventory tracking from Logimax WMS, you can monitor product stocks against estimates so if problems arise, they get resolved faster. Efficient WMS software from Logimax can also prevent future issues from happening altogether by providing an accurate picture of every product on hand in your warehouse or 3PL at any given time.

4. Get Your Team Involved

The more people involved in your inventory forecasting process, the better. Involving finance and operations will give you a better understanding of what’s happening with physical stock levels at any given time; while inviting external stakeholders can help identify potential problems before they arise by allowing input for future decisions that may affect them (ie. buying/selling).

5. The Right Tools Equal Success

Using the right tools to replenish inventory can be challenging during peak season. Consider technology solutions for your warehouse or 3PL like mobile carts, RFID tags, and warehouse management system software that will help you compare your results with your forecast in real-time.

Warehouse management is a challenging task during the peak season. However, with these added picking strategies you can create more efficient warehouse operations. A more efficient warehouse will help save your company time and money on inventory management and ensure data accuracy for future forecasts.

How Your Warehouse Management System Software Can Help

A warehouse management system (WMS) helps you easily access inventory management, track shipments, and keep an eye on your business. It also allows you to automate processes so you can focus more on growing your business instead of managing every aspect of it.

When you’re looking for a way to make your business more efficient, accurate, and effective at accelerating inventory turnover time then look no further than automating tasks with Logimax WMS software. The process will be streamlined thanks in part to integrations that can occur via API or online shopping cart interfaces. This allows the system not just to track what’s going on, but also to send updates as they happen. This means there are never any lost opportunities again.

Logimax WMS software reporting features can provide valuable information to help your customers plan their inventory levels. This is especially crucial this peak season as companies shift from JIT (Just-In-Time) strategies towards those that are focused on maintaining a higher level of availability, like JIC (Just-In-Case) stocking and material handling.

The best way for warehouses and 3PLs to plan ahead for peak season is by maximizing the benefits from their client relationships. To do this, you should communicate early and often with your customers. Talk regularly about schedules or upcoming promotions, as well as standards such as Black Friday and Cyber Monday.

Communication and real-time reporting during these busy times will help everyone be best prepared for a successful end of the year. For details on how Logimax WMS can help your company during peak season, contact us today!